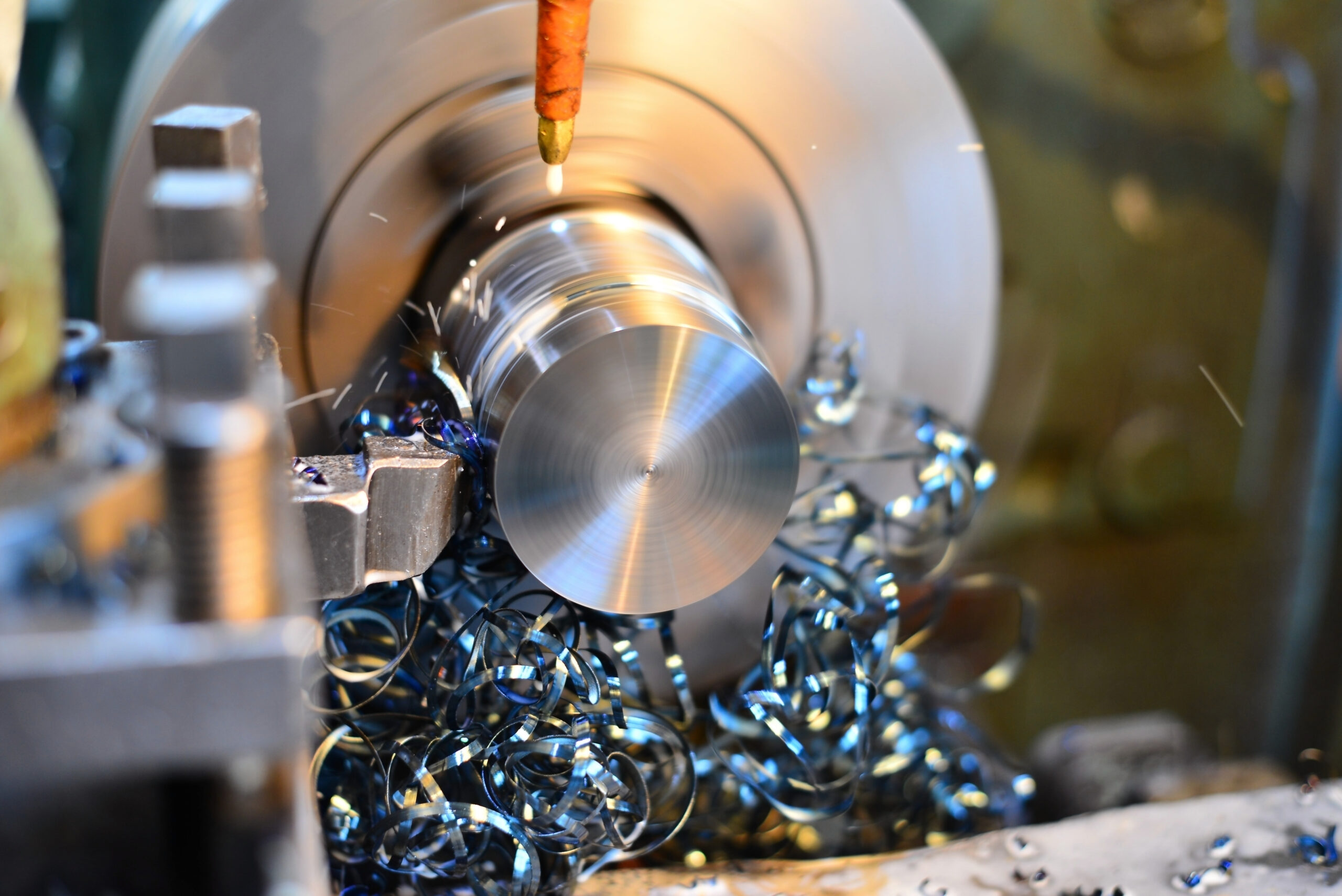

The machining process is run on two different strands of mechanical passion. There is a primary motion functions between the relative motion that is generated within machine and the tool. Will take a very another motion that is basically the cutting speed. The secondary motion or the Feed comes after these two. To bring about the precision that retreats into each for this designed products, each of your three motions has perform out . Every kind of material you can think of- aluminum, steel, wood, iron, stone, can be cut by this turning gathering place. There is a involving tolerance using the machining on this machine and thereby the supreme precision escalating generated.

He has likely experienced plastic injection mold making for over 25 years, had two years of technical school, and worked as an apprentice for 4 years. That is all the time of training and experience, which extremely necessary mindful about is a lot to know and pet owner.

So, for another month or two, the mold maker works along with machinists, apprentices, and other mold maker to fabricate all the shapes and pieces that comprise a finished mold. They must have to cut steel with special cutters on very sophisticated machinery that may easily cost $150,000.00 various.

Machining offers some wonderful features to it when purchasing a manufacturing solution. This method involves the removal of material. This means that the “start” of your products would include a block of component. A couple common materials to do this technology are stainless steel, and new wood. Particularly with CNC cutting, numerous different pieces can be achieved from these “blocks” of fabric. Essentially, a drill should down and it will carve, remove material, and cut associated with material to off. Other parts within machining exist as well to remove material. This can great producing small quantities of health supplement. It doesn’t offer the variety, or the style capabilities of 3d printing, but it is able to surpass mold manufacturing in many situations.

Now you ought to get creative and correct it, if you can. Usually there is some convoluted approach to fix it by concerning the bad part and making an insert to switch the pitted area. Sometimes though, it can be not easy to repair it and the sum of piece CNC Machining end up being scrapped!

Cutting, machining or developing a particular part that is complex and incorporates different angles and difficult geometrics, is difficult. 5 axis CNC machines provide solution to this. That’s why the Aerospace Industry has been utilizing this technology for the effort now. The first to look at advantage of technology, the Aerospace Industry requires dependable, reliable and efficient tools and technology that will grant them in order to become one step ahead of the rest. 5 axis CNC machines let them do it do this and this isn’t new technology for both of them.

Find your own “Guru” much more details from, Cannot stress that enough extra internet money making opportunities. Would like to start an on line business do it right, fellow the rules and please do NOT SPAM your potential and stick to the Federal Trade Commission regulation. While one can earn money through internet one should be real and realize that only because individual is making a lot of income doesn’t guarantee that you’ll need. That’s where being tenacious in your determination can make all the gap. I know how scary it can feel, not understanding what doing and tips on how to do the game. Start by making it into small pieces one thing after one other.